- engitech@mail.com

- Mon - Sat: 8.00 am - 7.00 pm

We are creative, ambitious and ready for challenges! Hire Us

We are creative, ambitious and ready for challenges! Hire Us

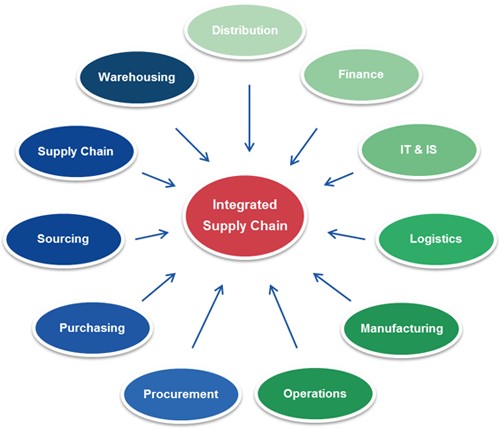

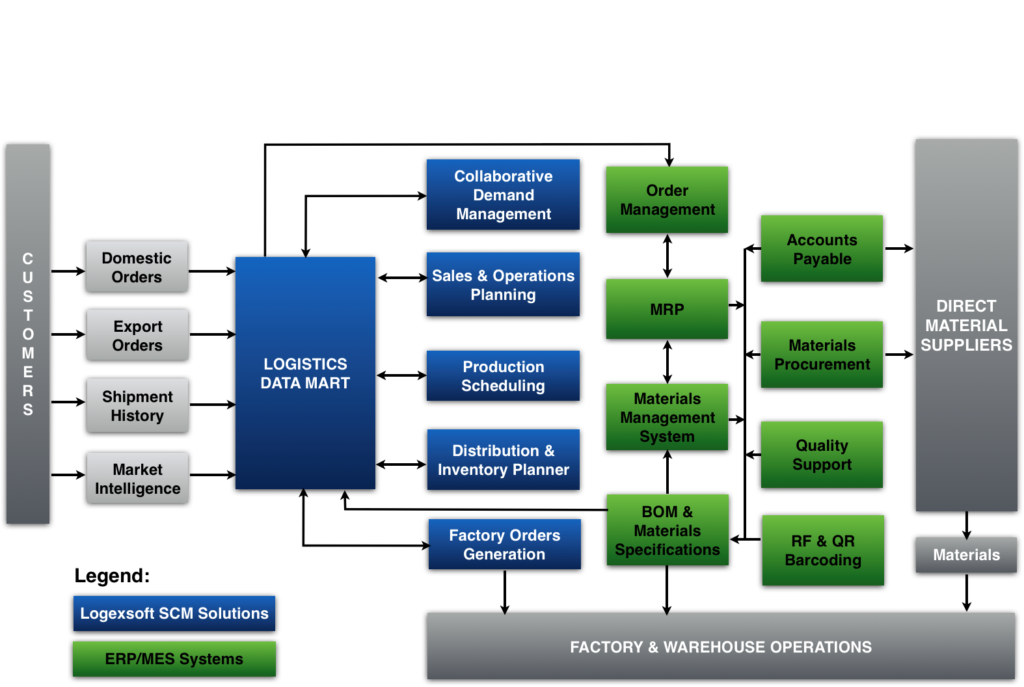

Manufacturing transactional systems (i.e. ERP, MES, Quality) can be large, complex, and contain disparate data. The Logistics Data Mart is an ODS (Operational Data Store) designed to harmonize data from multiple sources for alternate operations on the data, such as reporting, real-time analytics, decision support operations and more. It supports rapid, adaptable responses to changes in a business environment.

Ashlaketech worked very closely with the client to identify the following business challenges that were being faced on a regular basis:

Key Challenges were categorized, elaborated into the following:

Key Challenges were categorized, elaborated into the following:

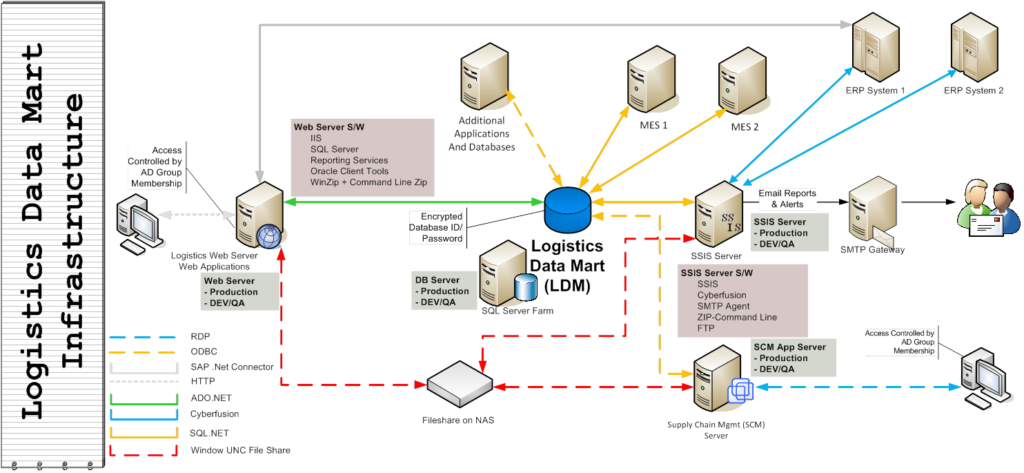

Here is a consolidated view of the interactions between the different supply chain, ERP, MES & other systems that LDM interacts with:

Additional, the dev environment had Visual Studio for development purposes.

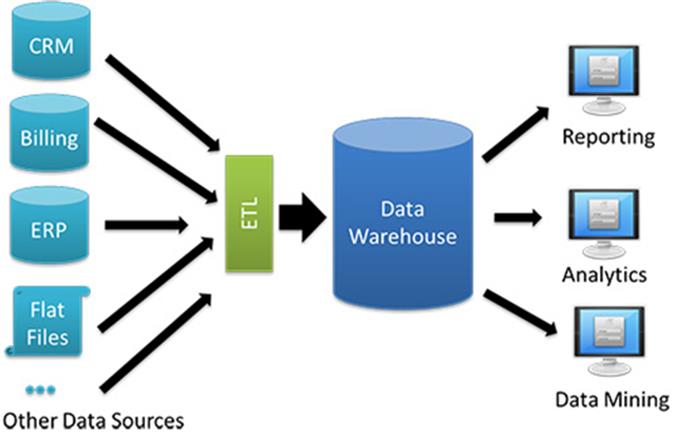

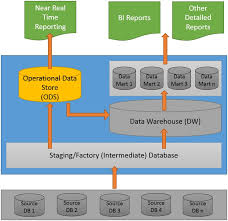

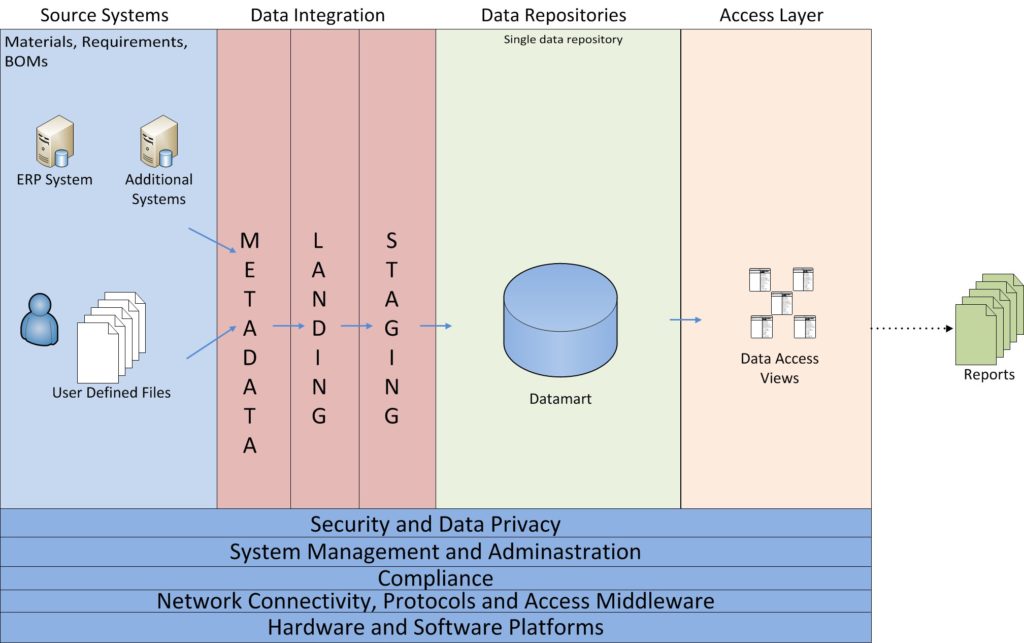

The following diagram shows the high-level data flow that was used in the design of the DataMart. Each section is further explained below the diagram:

Multiple systems of record were referenced to extract information via flat files dropped into a drop point folder. Interfaces were written (governed by formal data contracts) to load the data into the metadata & landing sections

This section contains master data or metadata required to support the loading and processing of data into the DataMart. E.g. BOM structure

This section is the initial entry point for the data loaded via SSIS packages from the source file. Data is retained in this section for a pre-defined period of time in case there are issues in the data load process

This section contains the transformation & harmonization of the individual data components prior to loading the data into the DataMart

This is the final resting place of the harmonized data that will be eventually used to build views to support reporting

These views are built to consolidate information from multiple sections of the DataMart to facilitate ease of reporting

This section contains ad-hoc and custom reports built to support reporting needs of the client

Required to support the architecture and infrastructure requirements of the client

Many businesses do not have the time or resources available to gather and process large quantities of information. This may lead to lack of information about:

It’s not always obvious what information is potentially valuable, so there is a need to gather as much data as possible as it relates to supply chain processes. Using a sophisticated database management system allows to store data that builds up over time and can become increasingly useful and valuable. For example:

In short, a disciplined approach to gather, enter and process enormous amounts of data that is coordinated, cleansed, harmonized and verified. This can help ensure that supply chain solutions are deployed faster, run more efficiently with high reliability and ensure that the business runs in a regulated and properly managed manner.

Client references available upon request