- engitech@mail.com

- Mon - Sat: 8.00 am - 7.00 pm

We are creative, ambitious and ready for challenges! Hire Us

We are creative, ambitious and ready for challenges! Hire Us

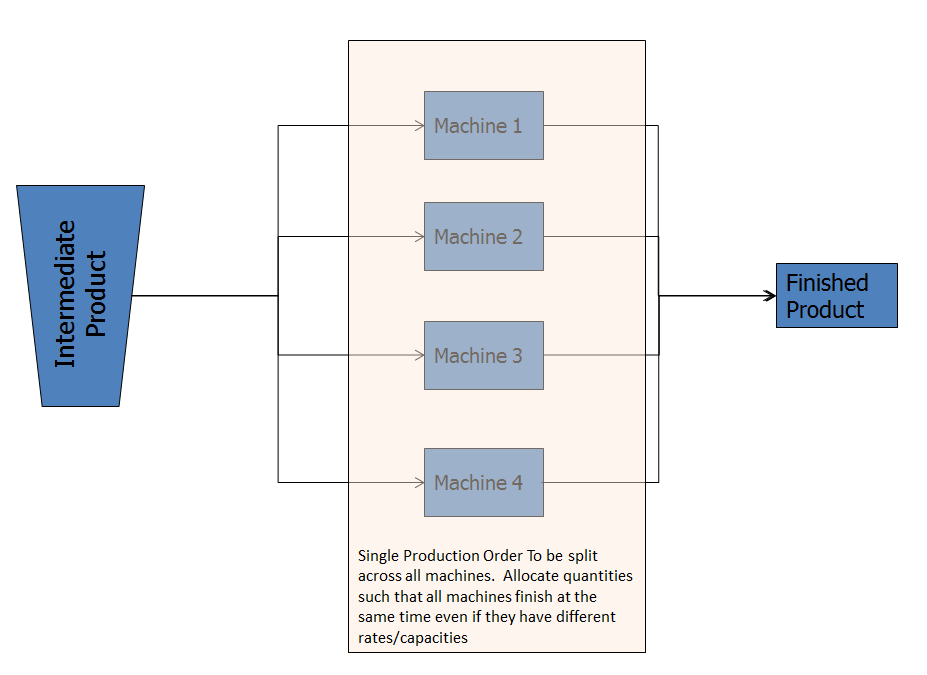

A single production order is split over multiple machines. The machines may run at different time effective rates, or may have machine specific shut down schedules different order priorities and production capabilities. Certain products may only run on a subset of the available machines.

The desired outcome is that the end time on all machines is the same. This is usually required because upstream supply of feed material is common and therefore has to be switched to the next product at the same time.

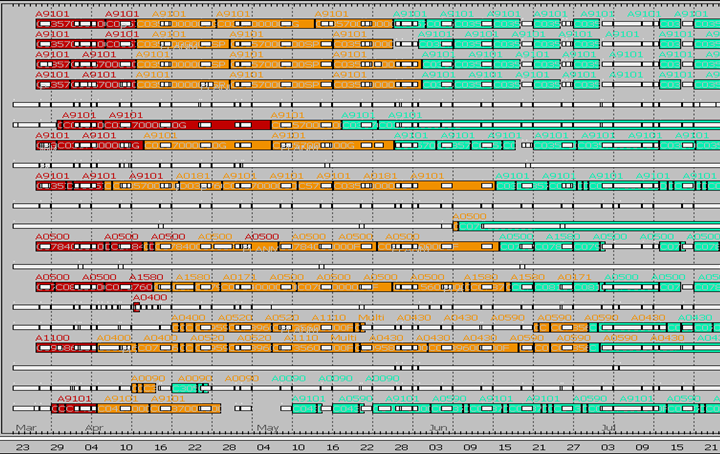

L ogexsoft has created a Dynamic Production scheduler using AspenTechTM SCM that recalculates the quantity to be assigned to each machine in order for the order to complete at the earliest time on all machines. The quantities are reassigned and updated multiple times a day as production actuals are received from the shop floor control systems. Changing the end time on one order has a ripple effect on downstream orders which also have to be re-synchronized.

The synchronizer handles different types of production orders:

T he synchronizer logic is called automatically in the background as the scheduler modifies order quantity, sequence, or modifies the number of machines and which machines are assigned to an order.

As there are a large number of orders the order synchronizer is smart enough to know when only a ‘local synchronization’ (synchronization only on orders that have modified and associated machines) verses a global synchronization which operates on the entire schedule.